6.1 We stumbled on an engineer crouched beside a washing machine, peering into its insides with a torch and muttering. He put off paying any attention to us until the last moment, then greeted us with a cheeriness that was a little forced - as if he were still thinking about an unsolved problem. When we asked to see some of the current projects, he launched straight away into a discussion about the washing machine.

6.2 "The Partnership decided to produce this washing machine," he said, "and I was the poor engineer given the job of co-ordinating the necessary resources to get it on the market. There are over a hundred partners, nearly every one from a separate home, so there�s a ready made captive market of at least a hundred. Other machines available are expensive, throw-away designs that our mechanic says he cannot repair. The partners filled in a questionnaire saying the features they wanted such as no planned obsolescence, high reliability and ease of maintenance with no water hammer effect during hydraulic switching. What you see in front of you is the first prototype of that �specification�. They reasoned that if they made a washing machine themselves, then they would get what they wanted in a machine at a reasonable price. As it happens the price is about the same as the prices ruling outside for �domestic� machines, but I believe this is because we have used components of an industrial quality to meet the reliability requirement. In the long term I expect the dollars per hour used over the life of the machine to be considerably less than competitive products, all things considered. Put another way, the cost/quality ratio is superior, as indeed it has to be if it is to join the ranks of our successful products. We don�t advertise so that helps our ratio a lot, and we sell direct so there�s no middle-men and that helps, but still we have a very low volume production and cannot justify the degree of automation of our multinational competitors. The partners will test the first batch of a hundred themselves. If sales are good we can automate a little and reduce our cost which will further increase sales - if all goes well we aim at a small but optimally sized plant. If we can achieve this our hold on the market is secure. Believe me it�s not easy and we have many more failures than successes. If I bring in one successful product each year - somewhere between 10% and 20% success rate - then I�ve earned my money."

6.3 "Have you any successful products that have passed the prototype stage and been successfully marketed?" I asked. "Of course," he replied. "What do you think are the economic sinews of The Partnership?" He motioned us into a showroom, which we soon found was like a private museum. It contained all The Partnership�s products from pocketknives to caravans that had been developed since the formation of the enterprise 150 years ago. We were impressed as we walked slowly past the exhibits taking careful note of the industrial history passing before our eyes. Most of the products were obsolete with major product changes shown prior to discontinuation. The current products were in a bay by themselves, and there didn�t seem to be anything extraordinary about any of them - just everyday things that are seen around everyone�s house.

6.4 The engineer commented on the ordinariness of the current product mix: "A research and development project can be successful without a technical breakthrough: a marginal cost and or quality advantage can attract considerable and sometimes spectacular sales. Although this enterprise is very much R & D oriented and recognises the necessity to remain technically superior in its successful product areas at least, a genuine breakthrough only occurs once in about ten years. Most of our products are, as you see, only marginally different - we consider them marginally superior, but that may be bias - from their competitors. Our clothes peg, for example, is still obviously similar to other clothes pegs. We�ve added an ultra violet filter to the plastic prior to injection moulding, and our engineers have designed very effective fillets around the main areas of stress concentration, but we�ve still got a common clothes peg which costs a little less than other pegs, because we sell direct and don�t advertise, and lasts a little longer."

6.5 "As you can see from the example of what we�re doing with this automatic washing machine, we only produce products that we need to use ourselves as a captive market. We do not try our prototypes on the open market - we use them ourselves first to clear the faults. We have an excellent reputation to protect and have no intention of reducing the high level of trust that our customers have placed in us over the years. On principle, we never make anything under licence since this would deprive our engineers of essential design experience, reduce our high level of technical creativity, and if a competitor put a more advanced design on the market we would run the unacceptable risk of not having the creative design capacity to improve our product and retain our market. Among the engineers and draftsmen in the design office there is a considerable pride in workmanship and the creative skills that have been developed over the generations - a technical heritage if you think of it that way. If we are approached for a licence by a lazy or incompetent firm, because they can see a market in their country for one of our products and they don�t want to make the effort of developing the product themselves and all they want is quick money, we are prepared to sell at a high price on tough standard terms. We make them buy our finished tooling, we bar them from all but their own home market, and we don�t even allow them the benefit of any technological advances we may make during the course of our work. Furthermore the agreement is for a fixed term, after which we regard their market as fair game, and we refuse to allow outsiders to use our trademarks since we are not prepared to place our good name at risk."

6.6 "For a Christian enterprise, aren�t you being a little tough on your business associates?" I asked. "I suppose we are," he replied, "but that�s the official policy of The Partnership. The minutes of those early meetings where this policy was hammered into shape are available, but I suspect the main reason for the harsh contractual requirements is a lack of respect for people who want money and don�t really care about the product or the engineering that has gone into it - The Partnership does not identify with their motives in general." I could see a flash in his eye and had the feeling that if I were in the market for a Partnership product manufacturing licence, I would be paying top dollar and probably wouldn�t even get a free lunch from their canteen when the deal was closed."

6.7 "Customer loyalty," said the engineer, "is very important to us. Technology has reached the stage of diminishing returns in that it takes considerable capital resources to achieve even minor product improvements. In some cases we have considered the development expenses too high for the small gain and have allowed competitors to approach our technical standard and even perhaps marginally surpass it. We have found in practice though that our customers continue to buy our product in such cases. This interested the partners sufficiently to undertake a consumer survey on the point and it was discovered that we have built a business that appeals in principle to many consumers and they identify with our goals to such an extent that they would continue to buy our products even if they were at a price disadvantage of about 10% for the same quality. We hope we will never deteriorate to this extent. It appears that some customers habitually ask for �Partnership Pegs� or �Partnership Honey� partly as a form of donation."

6.8 "There is no doubt in my mind that it is more profitable for Christians to spend their research dollar on people rather than products. Can you think of anything could make for anyone that they cannot already get the near equivalent of? If you can�t think of a single thing you understand that technology has reached the stage of diminishing returns."

6.9 "Chronic overproduction and underutilization of the means of production is the greatest problem manufacturers have to face this century. All capitalist economies have to grapple with the fact that they can no longer expect continually expanding markets: forced penetration into foreign markets is no longer tenable since the proliferation of nuclear weapons; population growths have stabilised at around 0.5% per year and we all have to face the fact that this is the rate at which we can allow our production to increase. We are I believe in a maintenance economy period of history and I am reflecting this in the current designs: products are being designed for ease of repair and maintenance and for a relatively long life."

6.10 "You will notice," said the engineer, "that there are quite a few products that are produced in quite low volumes. The reason for this is that over the years the partners have wanted various commodities and have produced them primarily for their own use, which is our practice for the introduction of a new product, but the outside demand has either tapered off or has never developed. Our consumption patterns are markedly different from the general population and this is reflected in our product mix. We have reached the stage now where a significant proportion of each partner�s personal consumption is produced here."

6.11 "I must say," said the engineer, "that there is considerable satisfaction in using my freedom to create my own products with which I will probably be associated for the duration of their economic lives. My creative streak has certainly been developed by these exercises."

6.12 "What makes it different in The Partnership?" I asked.

6.13 "There are many different aspects to our partnership life compared to conventional private enterprise. As an engineer I appreciate that The Partnership does not prototype on or use the public for quality control. The partners take the development risk and accept the teething problems of their new products so that they reach the market fully proven."

6.14 "Exactly what do you mean by �use the public for quality control�?" I asked.

6.15 "It has been found", replied the engineer, "that it is cheaper to dispense with close final quality control in the factory, and to replace it with a guarantee. Only if a consumer claims does the guarantee have to be honoured, and this quality check by the public is free to the maker. Thus the cost of final quality control is largely transferred to the consumer who has become used to bearing the lost time, annoyance, delivery costs and consequential costs associated with malfunctions due to poor quality control."

6.16 "Wouldn�t this approach restrict the products that you could contemplate producing? You could hardly expect to absorb the development costs of a motor car for example," I asked.

6.17 "An excellent point," conceded the engineer. "We do restrict ourselves to simple products within our capacity, but there is considerable interest in co-operating with our splinter partnerships and other religious partnerships in more ambitious developments where, for example, this partnership would make a component for a federation of religious partnerships. This conflicts with the general policy of only producing finished products for end-consumers, but it appeals in other religious co-operative respects, and Rule 5(d) may be amended to allow component manufacture in this specific area."

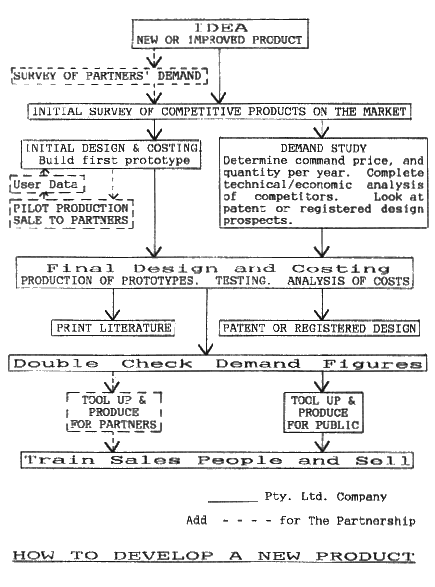

6.18 I observed on the wall of the engineer's office a chart of how to develop a new product:

From The Partnership, by Graeme Doel.

Converted to HTML by Simon Grant, 2003.